How much are glass splashbacks

My name is Bohdan Duha, I am the founder of CreoGlass Design, and in this article, I will explain How much are glass splashbacks, how are the splashbacks priced up and give you a ballpark figure for Bespoke, made-to-measure (not standard) sizes and designs.

Glass splashbacks for kitchens or bathrooms are rising in popularity due to their practical ease of cleaning and design versatility. With that, more and more of us want to know How much do splashbacks cost between 0 and 1 million? There is no single answer to these questions due to several factors.

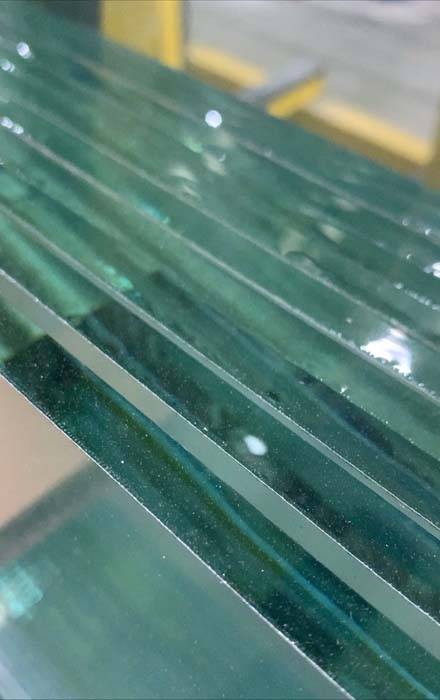

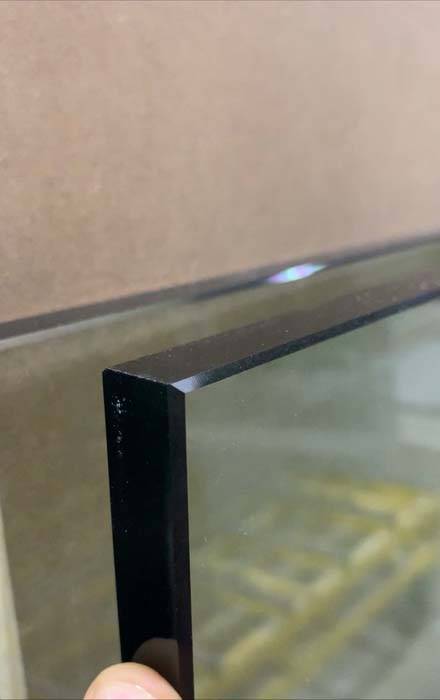

- SIZE MATTERS - price factor 1 First of all, size does matter. The price goes up with the square meters of glass. Glass splashbacks are generally made from 6mm low iron and toughened glass.

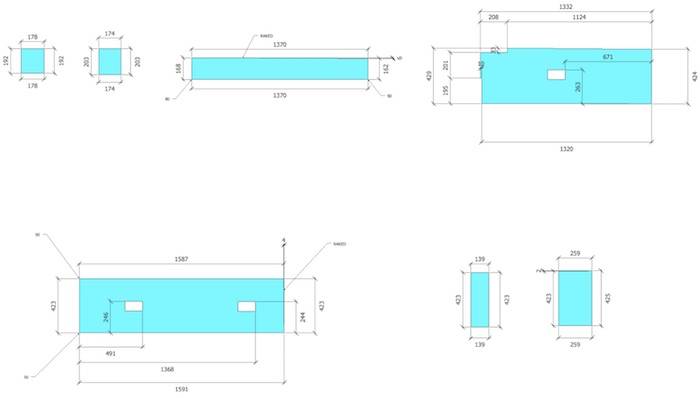

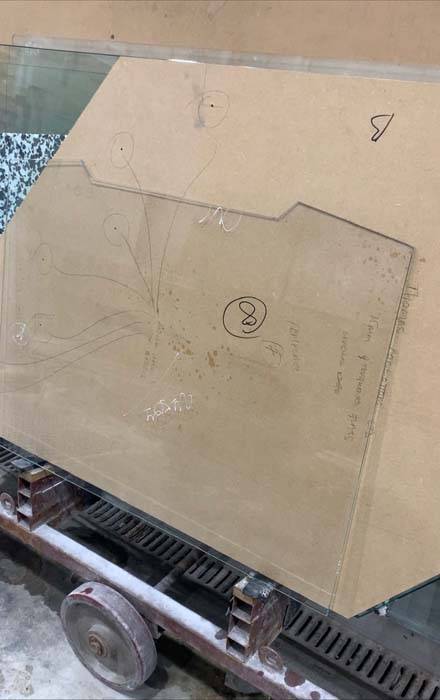

- SHAPING - price factor 2 Shaping of glass is a labour and tools intensive process. Glass splashbacks are not cut out from an already coloured sheet of glass, as some may assume. Each glass splashback panel cut individually from transparent glass.

EDGES All edges must be so-called polished, which means chamfered and smoothened. There is a linear meter charge for this process.

COUT-OUTS Socket cut-outs, holes, curves or notches are either shaped manually or with a water jet or CNC programmable machine. Each socket cut-out, hole, curvature or notch is priced individually.

TOUGHENING

Once the shaping process is completed, glass must undergo a heat strengthening process called toughening, which is essentially glass forging. This process requires large furnaces with a temperature of 620ºC.

This process makes the glass strong, impact-resistant, flexible and heat-resistant.

DESIGN COATING: A full-size bespoke kitchen glass splashback can consist of up 20 glass panels shaped and toughened individually to fit only one kitchen. They arrive in a transparent form called blanks to a CreoGlass specialist coating and design facilities in Watford. Here we inspect every single piece for quality assurance. They have to be manually re-measured and checked for any defects before they are colour coated, mirrored, or printed.

Plain colour splashbacks consist of one layer of specialist glass paint in the colour of your choice with a minimum of two coatings. Specific colours like yellow or lime green require more coatings due to low pigment coverage. Different designs require a different number of layers, materials and techniques, which reflects in labour hours. For example, some of our hand-made Stencilled designs may reach up to 15 layers. With this design, labour hours are the primary price factor. With our Premium or Mirrored Designs, like Mirror Stripes, Patterned Mirrors, Antique Mirrors or Toughened Mirrors, it is a combination of cost of materials and techniques = labour hours and the skill required to create this product. Finally, every CreoGlass splashback coated side is protected with a layer of aluminium foil for extra durability. CreoGlass Splashbacks are a ®CreoGlass Registered trademark. They come with up to 10 Years Warranty* and are made to last.

PRICE The entry-level price point is our classic splashbacks coated in plain colour. Please see attached ballpark guide price list for the year 2021.

Get In Touch

Contact us

Trade

Get In Touch

Contact us